ECOMARK LASER ENGRAVING

IN THE PHARMACEUTICAL INDUSTRY

The production of medicines and drugs is subject to the strictest and ever-increasing requirements for patient safety. In particular, protection against counterfeiting and tampering as well as traceability are requirements where absolutely secure and reliable labelling solutions play a key role. EcoMark offers you the know-how, the experience and the technical solutions with which the pharmaceutical industry can successfully fulfil these tasks.

ECOMARK LASER MARKING SYSTEMS:

HEALTHY SOLUTIONS FOR YOUR SUCCESS

When it comes to medicines and drugs, legible labelling can be vital. The guidelines set by the GMP (Good Manufacturing Practice) standards and the FDA (Food and Drug Administration of the USA) requirements are correspondingly demanding and binding for the pharmaceutical industry.

SPECIFIC CHALLENGES

ON LABELLING IN PHARMACEUTICAL PRODUCTION

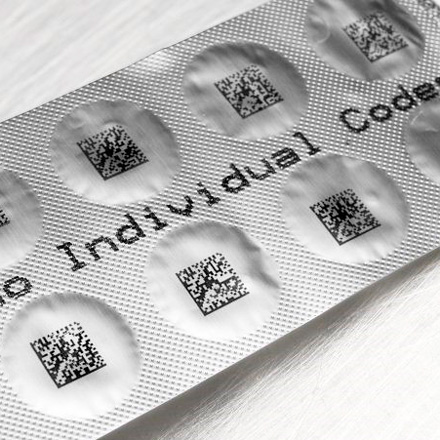

Each individual prescription medicine must be identified by a unique individual identifier that ensures traceability through the entire supply chain to the patient and back to the manufacturer. This includes: an individual serial number (serialisation), a unique product code, date of manufacture, production batch and expiry date. This information must also be machine-readable, with appropriate coding, especially data matrix codes, being used.

Each medicine is registered in a national database. When the medicine is dispensed in the pharmacy, a comparison is made in the system and only then is the medicine handed out to the customer and registered as administered in the database. This ensures that the patient receives the correct medicine and not a counterfeit. This also makes possible any recall actions.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationThis means that pharmaceutical products must be reliably marked in a permanently durable and easily legible manner. The labelling, especially the machine-readable codes, must not be able to be damaged by mechanical abrasion, nor by chemical action, acids, temperature influences, etc.

Laser markings fulfil these requirements perfectly. That is why laser marking systems have long been the means of choice in the pharmaceutical sector.

LASER MARKING MACHINES

FOR ALL APPLICATIONS AND MATERIALS

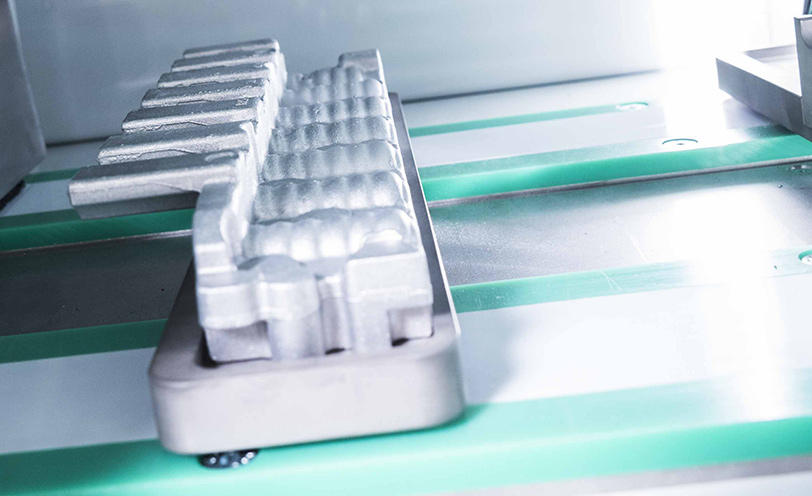

Laser marking systems from EcoMark are suitable for all materials required for pharmaceutical products, whether ampoules made of glass, injection syringes made of metal, cannulas made of plastic, blister packs with aluminium, label stickers or folding boxes made of paper. All the necessary information can be lasered. Manufacturer logos, graphics and micro lettering are also possible.

The high-quality technology of our machines ensures optimum quality and efficient, cost-effective processes. An integrated automatic quality control removes any defectively marked parts from further processing.

The EcoMark control software also provides all the necessary interfaces for integration into highly automated manufacturing processes and for connection to databases.

Expert, comprehensive advice is just as important as perfect technology. As an experienced partner to the pharmaceutical industry, we support you in all aspects of selecting and designing the solution that perfectly suits your needs. Talk to us about your requirements.

- TALK TO US ABOUT YOUR IDENTIFICATION PROCESSES: We will advise you comprehensively about your advantages and possibilities. And if we don't have a ready-made solution yet, we'll find it together with you!

LIMITLESS AREAS OF APPLICATION

Information for traceability, quality control or compliance with legal requirements, protection against brand piracy and plagiarism, classic branding with brand logos, infographics or machine-readable coding for automated production control: the spectrum of possible and useful applications of laser marking is endless.

TAILOR-MADE: INDUSTRY SOLUTIONS FROM ECOMARK

Well-founded application know-how is the basis for optimal solutions that inspire our customers. As an experienced partner for industrial laser marking, we know your industry and can advise and support you individually in your specific needs.

NOBLE BRAND DESIGN

Precise laser engraving of high-quality aluminium profiles with different lengths and surface coatings.

Traceable coding

The aim was to apply a DMC code to a die-cast aluminium gearbox housing by laser marking.