MAXIMUM PERFORMANCE IN MINIMUM SPACE:

ECOMARK EASY BRANDING COMPACT

Easy Branding is an innovative concept with which EcoMark

completely redefines the laser marking machine.

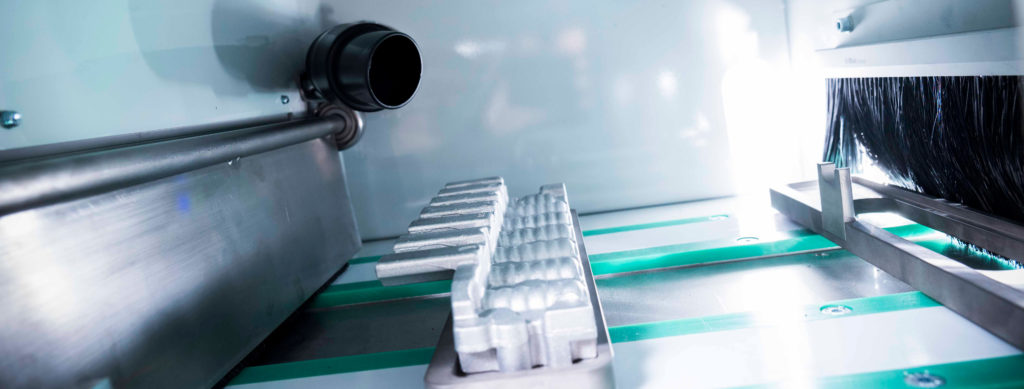

With Easy Branding Compact, there is now the first laser series machine with which you can quickly and easily get started in automated and highly precise laser marking. Particularly suitable for small parts and bulk goods made of a wide range of materials. As an optional extra, a vibratory bowl is available as a vibratory feeder for the correct positioning of bulk material parts, matched to the Easy Branding Compact laser machine.

Thanks to the compact design, you save space and can usually also integrate the machine into existing production lines without any problems. This allows you to benefit from the superior advantages of the EcoMark Easy Branding series in the smallest possible space.

HIGH PRECISION LASER MARKING,

PERFECTLY INTEGRATED INTO YOUR WORKFLOW

The laser engraving machines of the EcoMark Easy Branding series adapt easily to your industrial manufacturing processes and can also be used in automated processes and in Industry 4.0. This also applies to the Compact variant.

Thanks to the unique, intuitive Windows-based EcoMark software, you have unlimited flexibility in using the laser marking machine. New workpieces can be easily created, taught in and set up in no time at all, eliminating the need for lengthy and time-consuming changeovers. With the EcoMark software, your specialists can quickly change the machine over to new products at any time. Any number of different workpieces can be stored in the database and called up again at any time. Interfaces for data exchange with a central PLC or your production system are available.

If questions arise, we provide quick assistance - often remote maintenance is sufficient.

AS PRODUCTIVE AS IT IS PRECISE: INVEST IN MORE PERFORMANCE

With the Easy Branding Compact laser marking machine from EcoMark, you can mark laserable small parts and bulk materials made of virtually all materials used in industrial processing precisely and particularly quickly at the same time. The possible throughput is extremely high with up to 5 laser markings per second and up to 18,000 parts per hour.

High-quality 3D and 2D cameras detect products and the position of the workpieces on the belt in fractions of a second and control the laser alignment on the fly. The latest laser and camera technology from leading manufacturers ensures the absolute precision of the laser marking, where a measuring accuracy of less than 0.2 mm can be achieved. Any incorrectly marked parts are automatically detected and rejected.

The expected service life of the laser marking technology used is usually between 50,000 and up to 100,000 operating hours - that's a good 10 years of use in continuous operation.

SMALL DIMENSIONS - GREAT EFFICIENCY:

YOU BENEFIT FROM ECONOMIC ADVANTAGES

Like all Easy Branding laser marking systems, our compact machine already offers superior economic advantages due to the innovative series construction concept: Compared to special machines, the laser marking machines of the EcoMark Easy Branding series score with lower development and construction costs. This enables faster delivery times and also ties up less capacity on the customer side. Added to this are low costs in ongoing operation, without consumables. The intuitive software that saves staff time and effort. The reliable quality and ease of maintenance of EcoMark quality machines, which reduces downtime. In the total cost calculation, laser marking with Easy Branding Compact is economically superior to many other marking systems.

And you buy without risk: thanks to the series construction, you can see in advance how your future machine will work in real use instead of having to deal with abstract design models and prototypes. So you are sure from the outset that you are getting a proven solution that can be used without any problems.

CONCENTRATED PERFORMANCE WITH UNCOMPROMISING QUALITY

As in all EcoMark laser machines, only high-quality components from leading brands are used in the Compact version. In particular, the camera technology and laser technology suppliers are carefully selected and must meet the highest standards. Since EcoMark as a manufacturer of laser marking machines is independent of laser manufacturers, we can choose freely from all manufacturers of quality lasers and offer the optimum solution for each customer's needs and wishes.

ALL LASER TYPES: A STRONG PROGRAMME

CO2 LASER

The carbon dioxide laser is one of the most commonly used lasers for laser marking in industry. A CO2 laser marking machine is very efficient and cost-effective, this type is suitable for a wide range of applications in industry. As experienced CO2 laser marking machine suppliers, we will be happy to advise you on the right solution for you.

FIBRELASER

The fibre laser or solid-state laser is also widely used for laser engraving applications. The fibre laser offers the highest beam quality and energy density. It is therefore ideal for laser engraving high-density materials. We would be happy to discuss with you whether a fibre laser engraving machine is right for you.

YAG-LASER

The YAG laser belongs to the solid-state lasers and can be guided through a glass fibre cable due to its low wavelength. It is mainly used for special requirements in the field of plastics, labels and foils. When a YAG laser marking system is suitable for your needs is best clarified in a personal discussion.