Laser marking systems for laser marking

in the automotive industry

The automotive industry is known to be one of the most demanding industrial sectors of all. This applies to the requirements for quality and safety as well as to the productivity and efficiency of the manufacturing processes.

It's a good thing that EcoMark laser markers can offer equally convincing solutions for all requirements.

ECOMARK LASER MARKING:

FUNCTIONALITY IN HARMONY WITH THE BRAND LOOK

In addition to safety, traceability and protection against counterfeiting, design also plays a major role in automotive labelling. Whether decorative elements or functional components such as control elements in the cockpit or switches in day/night design: the brand look should also be reflected in the value and quality of the lettering and markings that are visible in the vehicle.

SPECIFIC CHALLENGES

ON LASERS IN AUTOMOTIVE ENGINEERING

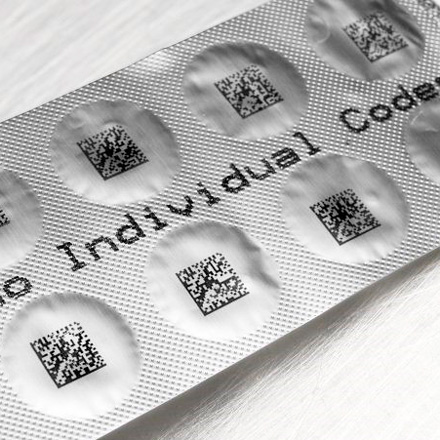

For reasons of safety and product liability, the complete traceability of components is an absolute must. An indispensable prerequisite for this is clear, permanently durable and forgery-proof marking or labelling of the components. In addition to lettering and numbers, logos and certification marks, coding, especially data matrix codes, are also used for this purpose.

During their life cycle, vehicle components are exposed to extreme stresses due to heat, cold, mechanical stress, wetness and chemical effects such as road salt. The markings must not be damaged in the process, but must remain intact and legible under all circumstances.

Marking systems for car manufacturers and their suppliers must ensure high-quality results with different materials. This requires different laser processes. At the same time, the marking systems must be robust enough to work reliably in the often harsh manufacturing environments.

In addition, production in the automotive sector is highly efficiently clocked. Marking processes that want to keep up here must be able to integrate into automated production processes and ensure a fast throughput with consistently high quality. A permanent 24/7 availability of the marking systems without downtimes is expected, and this with as little maintenance as possible over as long a service life as possible.

Equally important is a high degree of flexibility when different parts have to be labelled. It should be possible to change over the equipment quickly and without extra effort. The control and operation of the machines should also be as simple as possible so as not to tie up expensive manpower capacities.

Progressive miniaturisation and the diversity of components and materials place special demands on laser technology. Circuit boards, chips, switches, cables, sensors, housings, connectors - the range of components is almost endless.

Markings include serial and batch numbers, Datamatrix codes, logos, schemes, certification marks, quality seals, operating symbols and much more. All this even in extremely limited space and thus without tolerance ranges for the labelling.

The numerous materials from which the components are made are also challenging. Plastics, different metal alloys, coatings or lacquers are used and must be marked in consistent quality. Electronic components are also highly sensitive products - the marking processes must be designed to be correspondingly gentle.

ECOMARK: INDUSTRY PARTNER FOR

INTELLIGENT, PRODUCTIVE SOLUTIONS

It is no coincidence that the requirement profile of the automotive industries reads like a description of the EcoMark advantages.

Our high-performance laser marking solutions are designed for industrial applications with the highest demands. In particular, the uniquely intuitive and expandable EcoMark software enables flexibility and ease of handling like no other system. EcoMark laser marking machines are therefore ready for Industry 4.0 today - also for laser marking used for production control.

We would be happy to ensure efficient, cost-effective processes, durable marking and top-quality marking results that you can be proud of. Talk to our experts.

- TALK TO US ABOUT YOUR IDENTIFICATION PROCESSES: We will advise you comprehensively about your advantages and possibilities. And if we don't have a ready-made solution yet, we'll find it together with you!

LIMITLESS AREAS OF APPLICATION

Information for traceability, quality control or compliance with legal requirements, protection against brand piracy and plagiarism, classic branding with brand logos, infographics or machine-readable coding for automated production control: the spectrum of possible and useful applications of laser marking is endless.

TAILOR-MADE: INDUSTRY SOLUTIONS FROM ECOMARK

Well-founded application know-how is the basis for optimal solutions that inspire our customers. As an experienced partner for industrial laser marking, we know your industry and can advise and support you individually in your specific needs.

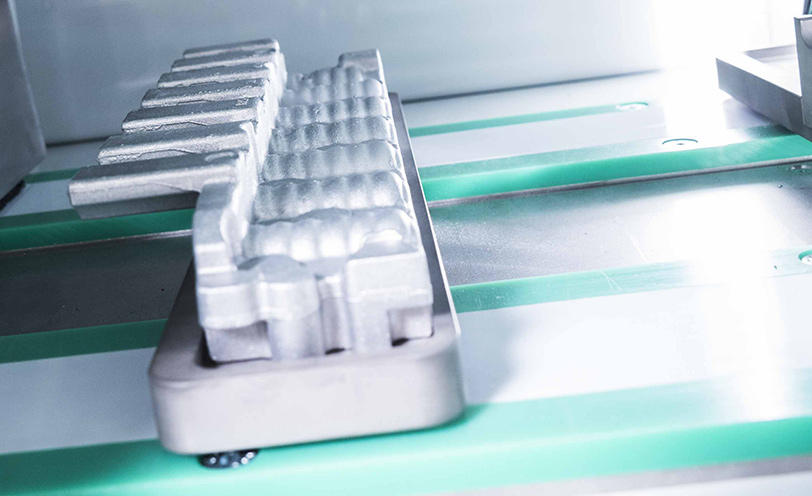

NOBLE BRAND DESIGN

Precise laser engraving of high-quality aluminium profiles with different lengths and surface coatings.

Traceable coding

The aim was to apply a DMC code to a die-cast aluminium gearbox housing by laser marking.