ECOMARK LASER MARKING

IN THE METAL INDUSTRY

Labeling, marking and coding in the metal industry

In the metalworking industry, modern laser solutions for permanent, high-quality marking of parts and products have long been indispensable. For companies such as suppliers to the automotive industry, steel or sheet metal manufacturers, machine and plant builders, producers of household appliances or manufacturers of medical instruments and devices, the main issues are traceability and quality assurance as well as brand protection and plagiarism prevention.

This is precisely why EcoMark's laser machines offer needs-based, customized solutions that combine perfect product marking with maximum productivity, efficiency and cost-effectiveness.

GRAVE ARGUMENTS:

METAL MARKING WITH ECOMARK

There are many good reasons why laser marking is by far the preferred form of product marking in metalworking operations today compared to other marking solutions. Particularly important are factors such as the high marking speeds, low consumption costs and surprisingly low maintenance requirements. Another advantage is that laser marking does not require the consumption and payment of other consumables such as ribbons, ink and make-up.

Above all, however, laser markings are permanently durable and highly resistant to chemical, mechanical, thermal and weather-related stresses of all kinds, as are common both in the usually harsh production environment of the manufacturing halls and in the subsequent use of the products.

ECOMARK EASY BRANDING:

METAL MARKING PERFECTED

Various processes are available for marking metals using lasers, such as laser engraving or annealing. Metals of all types are best marked with fiber lasers. Very high marking speeds, extremely fine beam strengths for maximum accuracy, excellent visibility and legibility, and the permanent abrasion resistance and indestructibility of the markings are unbeatable advantages. Intentional removal of laser markings is also not possible; visible processing traces would always remain.

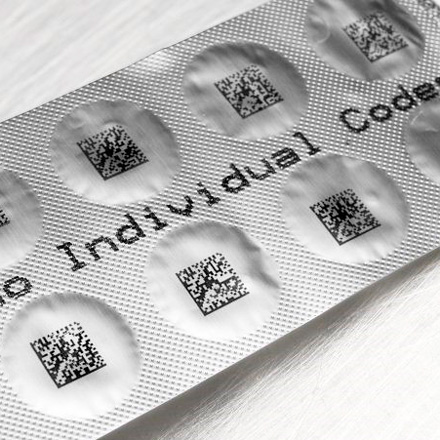

By means of laser engraving or color change, virtually all marking requirements in metal processing can be met: Variable data, serialized alphanumeric character sequences, data matrix, bar and bar codes, type designations and units of measurement, quality marks and other graphic elements, as well as logos for the permanent branding of product surfaces. Different marking sizes are feasible, from fine, filigree structures to large-area markings.

With EcoMark's laser marking machines, there are practically no limits to metal marking. Laser technology can be used to mark a wide variety of metals and alloys, such as stainless steel and structural steel, copper, nickel, brass and zinc, aluminum and titanium, whether with coated or untreated surfaces. The sophisticated technology of the machines ensures high throughput speeds and thus particularly productive processing operations. The machines fit perfectly into any production environment and offer all the necessary interfaces for integration into highly automated manufacturing processes and for connection to databases. They are therefore ideally suited to the requirements of Industry 4.0.

Another special and unique advantage are the extremely short setup times and the particularly easy handling. Especially when frequently changing metal parts and parts with different metal compositions are to be laser marked in the company, you benefit from the intuitive EcoMark control software. This allows all EcoMark machines to be set up for new marking parts at lightning speed, easily and without any major personnel or labor input. Highly flexible and efficient production flows are thus ensured.

Our low-maintenance, long-life laser machines are available in a variety of sizes for a wide range of applications, from hand-held booths to Easy Branding series machines to specialized custom machines, from small and bulk parts to tubes and complex-shaped parts to massive workpieces such as engine blocks and plant components.

If you would like to know more, our EcoMark laser specialists are always happy to help. With our expertise and broad experience with different laser applications in the metal industry, we will advise and support you comprehensively and develop your optimal, customized laser marking solution. Simply arrange a meeting!

- TALK TO US ABOUT YOUR IDENTIFICATION PROCESSES: We will advise you comprehensively about your advantages and possibilities. And if we don't have a ready-made solution yet, we'll find it together with you!

LIMITLESS AREAS OF APPLICATION

Information for traceability, quality control or compliance with legal requirements, protection against brand piracy and plagiarism, classic branding with brand logos, infographics or machine-readable coding for automated production control: the spectrum of possible and useful applications of laser marking is endless.

TAILOR-MADE: INDUSTRY SOLUTIONS FROM ECOMARK

Well-founded application know-how is the basis for optimal solutions that inspire our customers. As an experienced partner for industrial laser marking, we know your industry and can advise and support you individually in your specific needs.

NOBLE BRAND DESIGN

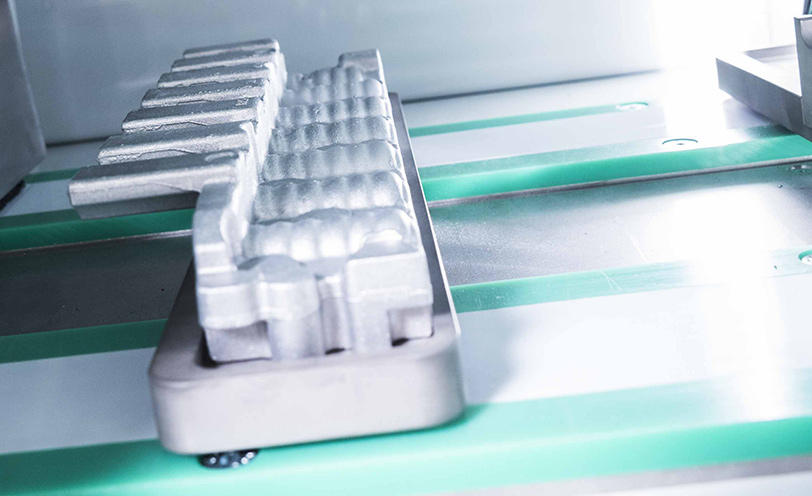

Precise laser engraving of high-quality aluminium profiles with different lengths and surface coatings.

Traceable coding

The aim was to apply a DMC code to a die-cast aluminium gearbox housing by laser marking.