LASER MARKING RETHOUGHT: EASY BRANDING BY ECOMARK

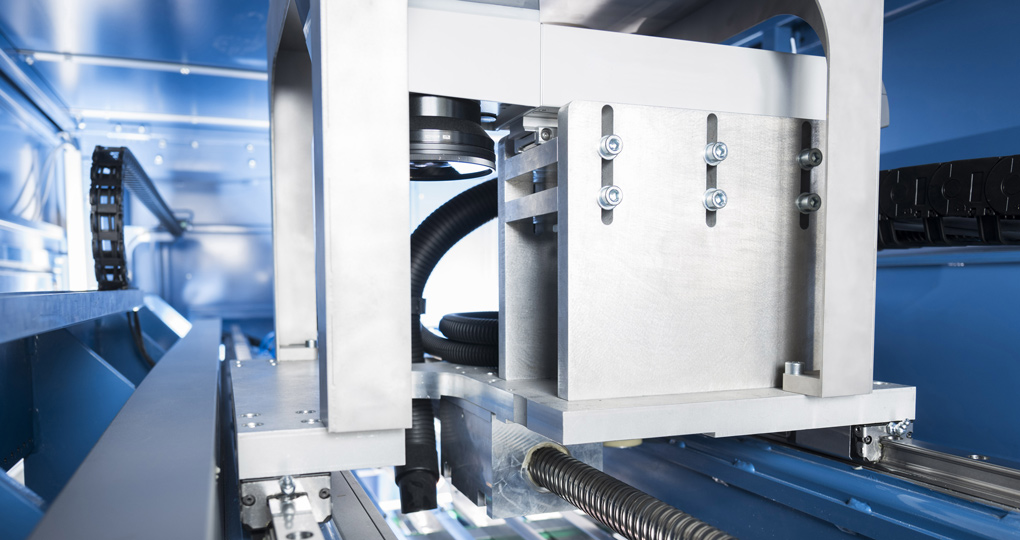

Easy Branding is an innovative concept with which EcoMark

completely redefines the laser marking machine.

The revolutionary idea: Intelligent series construction according to the modular principle allows the majority of all requirements for marking lasers for industrial use to be solved optimally and customised to fit. Our industrial customers benefit from special advantages compared to special machine construction. Among all machine suppliers for laser marking, we are the only ones with this concept.

The software for our labelling machines has been even more radically rethought. The user interface is uniquely simple and intuitive. PLC knowledge is not necessary - anyone who knows Windows can also easily control any Easy Branding laser marking machine, quite simply via a touchpad. This makes handling much easier and safer and the marking process more economical for you overall.

SUPERIOR SOLUTIONS:

FOR FASTER, MORE FLEXIBLE AND MORE PRODUCTIVE MARKING PROCESSES

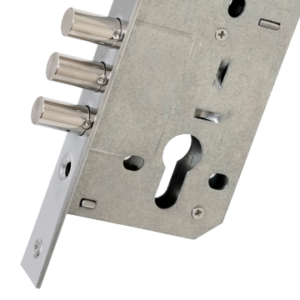

Laser marking is the best choice for many materials and industries today. Texts, numbers, graphics and codes can be applied directly to the parts to be marked. Durable and tamper-proof.

Lasers write extremely quickly, precisely and reliably. Compared to other marking methods, laser marking machines do not require any consumables such as ink, ribbons or labels - this pays off economically and ecologically in the long run. In addition, lasers mark without contact, so you can also laser-mark uneven and sensitive surfaces. Another advantage of laser marking is the high resistance of the marking to mechanical stress and chemicals. Due to these positive characteristics, modern marking lasers are among the most reliable systems for the most professional marking applications in industry.

Easy Branding laser engraving machines make laser marking particularly attractive to a wide range of industrial users.

EASY BRANDING: LASER MARKING MADE EASY

Here the name says it all: Our laser marking machines of the Easy Branding series make your life easier. Special workpiece holders are not required. You can also save on aligning small and bulk parts: All parts to be marked can simply be placed on the conveyor belt of the marking machine or poured chaotically.

In the first station in the laser chamber, the parts are measured three-dimensionally using a 3D camera. The software calculates the alignment and position of the parts and transfers the data to the marking laser. The laser beam is automatically positioned correctly and the laser engraving is also fully automatic. In the last station, the quality of the marking is checked. This I/O check makes it easy to reject parts that may not be perfectly marked.

PERFECT INTEGRATION: COUNT ON COMPETITIVE PROCESSES

An Easy Branding laser engraving machine always adapts to your workflow. The clever marking machines can be easily integrated into your manufacturing processes, even into existing production lines in your factory. They are therefore ideally suited for automated processes and are ready for Industry 4.0.

Interfaces for data exchange with a central PLC or your production system are available. For Siemens Simatic S7 with TIA Portal or Beckhoff controllers, axis designs and controls are already available as ready-made modules. This means that you only need to enter the system-specific parameters in the EcoMark software.

LIMITLESS FLEXIBILITY: ONE MACHINE FOR MANY WORKPIECES

New workpieces can be created and set up in no time at all. The intuitive software of the laser marking machine enables your specialists to quickly learn and change over to new products. Time-consuming set-up times or investments for new workpieces are thus eliminated. You can save any number of different workpieces in the database and call them up again at any time. If questions arise, we can usually help quickly via remote maintenance.

SUPERIOR PRODUCTIVITY: MORE IS POSSIBLE WITH EASY BRANDING

With laser marking machines from EcoMark, you can precisely and reliably mark laserable parts of a wide range of materials and sizes up to 3 mm. Product recognition takes place with a measuring accuracy of 0.05 mm. With up to 5 laser markings per second, an extremely high throughput can be achieved, even up to 18,000 parts per hour for small parts and bulk materials. The expected service life of the laser marking technology used is usually between 50,000 and up to 100,000 operating hours - that's a good 10 years of use in continuous operation.

CONVINCINGLY ECONOMICAL: MANY ADVANTAGES AS STANDARD

Easy Branding laser marking systems already offer enormous cost advantages due to the innovative series construction concept: Thanks to the lower development costs, low operating costs, simple software and ease of maintenance of the quality machines, laser marking with Easy Branding is often economically superior to other marking systems.

Compared to special machines, the EcoMark Easy Branding laser marking machines also score with shorter development and delivery times and purchase without risk: When making your purchase decision, you have the security of getting a proven, ready-to-use solution. You can experience your future machine in use in advance and do not have to rely on prototypes.

UNCOMPROMISING QUALITY: ALWAYS THE BEST CHOICE

We only use high-quality components from leading brands and set the highest standards, especially for laser technology suppliers. As an independent manufacturer of laser marking machines, EcoMark is not bound to any laser supplier - this means that we can freely choose from all manufacturers of quality lasers for every customised solution. We are also happy to install special components according to your wishes.

ALL LASER TYPES: A STRONG PROGRAMME

CO2 LASER

The carbon dioxide laser is one of the most commonly used lasers for laser marking in industry. A CO2 laser marking machine is very efficient and cost-effective, this type is suitable for a wide range of applications in industry. As experienced CO2 laser marking machine suppliers, we will be happy to advise you on the right solution for you.

FIBRELASER

The fibre laser or solid-state laser is also widely used for laser engraving applications. The fibre laser offers the highest beam quality and energy density. It is therefore ideal for laser engraving high-density materials. We would be happy to discuss with you whether a fibre laser engraving machine is right for you.

YAG-LASER

The YAG laser belongs to the solid-state lasers and can be guided through a glass fibre cable due to its low wavelength. It is mainly used for special requirements in the field of plastics, labels and foils. When a YAG laser marking system is suitable for your needs is best clarified in a personal discussion.