EcoMark laser marking and laser engraving

in electronics, electrical engineering, electrical and electronics industry

Electronic components are getting smaller and smaller - but still have to be provided with more and more information. And this must be precise and permanently legible. In addition to the information function, the details also serve for tracking and protection against product piracy. In addition, there are high demands on the productivity and speed of the marking systems to ensure the required high production output. No other marking technology is as predestined for these tasks as laser marking.

ECOMARK LASER MARKING:

HIGHEST PRECISION IN THE SMALLEST SPACE

EcoMark laser marking offers high durability and abrasion resistance of the marking under all circumstances. And this already for markings in the range of a few millimetres and with a throughput of up to 18,000 pieces per hour, depending on the size of the components to be lasered.

SPECIFIC CHALLENGES

ON LASERS IN THE ELECTRONICS INDUSTRY

Progressive miniaturisation and the diversity of components and materials place special demands on laser technology. Circuit boards, chips, switches, cables, sensors, housings, connectors - the range of components is almost endless.

Markings include serial and batch numbers, Datamatrix codes, logos, schemes, certification marks, quality seals, operating symbols and much more. All this even in extremely limited space and thus without tolerance ranges for the labelling.

The numerous materials from which the components are made are also challenging. Plastics, different metal alloys, coatings or lacquers are used and must be marked in consistent quality. Electronic components are also highly sensitive products - the marking processes must be designed to be correspondingly gentle.

ECOMARK INDUSTRY SOLUTIONS:

PERFECTION IN QUALITY AND PROCESSES

EcoMark offers you customised, on-demand solutions for all electronic component marking requirements, ensuring you get the best possible marking quality. This includes EcoMark's uniquely intuitive control software, which saves time and money and gives you exceptional flexibility. This allows you to quickly and easily change over your EcoMark laser machine to different products, without major set-up and adjustment effort. The software also offers all interfaces for integration into fully automated production environments, incl. documentation and connection to databases.

At EcoMark, you are guaranteed to find a perfect solution that inspires you. Our experts understand your business and provide you with comprehensive advice.

- TALK TO US ABOUT YOUR IDENTIFICATION PROCESSES: We will advise you comprehensively about your advantages and possibilities. And if we don't have a ready-made solution yet, we'll find it together with you!

LIMITLESS AREAS OF APPLICATION

Information for traceability, quality control or compliance with legal requirements, protection against brand piracy and plagiarism, classic branding with brand logos, infographics or machine-readable coding for automated production control: the spectrum of possible and useful applications of laser marking is endless.

TAILOR-MADE: INDUSTRY SOLUTIONS FROM ECOMARK

Well-founded application know-how is the basis for optimal solutions that inspire our customers. As an experienced partner for industrial laser marking, we know your industry and can advise and support you individually in your specific needs.

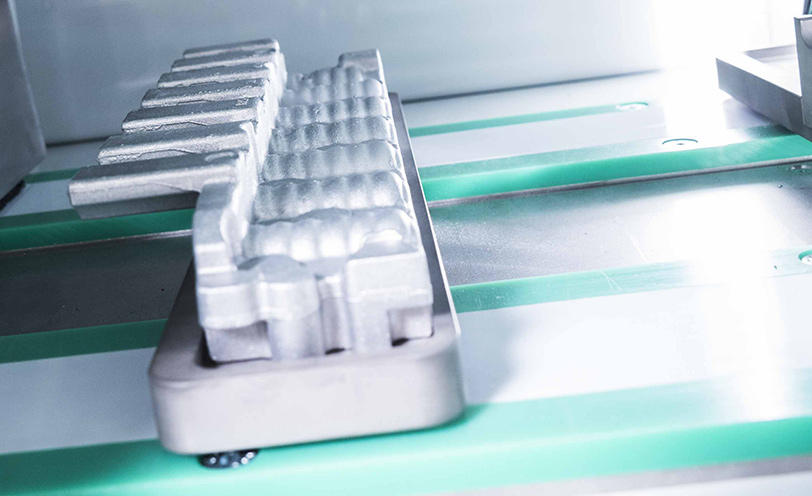

NOBLE BRAND DESIGN

Precise laser engraving of high-quality aluminium profiles with different lengths and surface coatings.

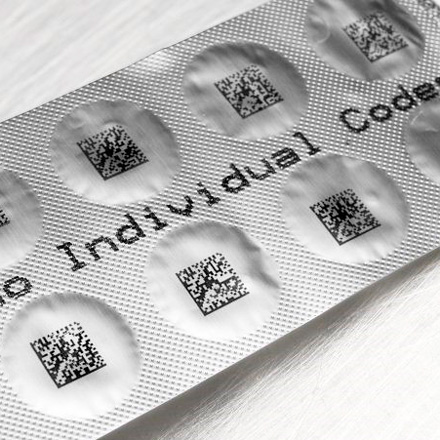

Traceable coding

The aim was to apply a DMC code to a die-cast aluminium gearbox housing by laser marking.