LASER MARKING MACHINES: STATE OF THE ART

Whatever you want to mark:

With us you will find the right answer to your industrial laser marking requirements.

With our unique machine and software concepts and state-of-the-art, high-quality laser technology, we enable you to have efficient, highly precise and uniquely productive marking processes. For all surfaces and materials. For small to large series. For sensitive and solid materials. For large and millimetre-small parts. And for safe, reliable continuous use.

EVERYTHING YOU NEED: THE ECOMARK LASER MACHINE RANGE

SIMPLY BETTER FOR THEM:

INTELLIGENT SOLUTIONS FOR YOUR SUCCESS

EcoMark solutions for laser engraving are different from all other marking machines in laser machine construction. Through an intelligent modular system, they combine the advantages of series machine construction with the individuality of special machines. This means: You get the optimal solution in every case and benefit from shorter development times and lower costs.

Equally unique is our own software with the intuitive user interface that anyone who can handle a normal tablet can master immediately. This facilitates machine control and saves a lot of time and personnel. The software also provides real-time data and offers all interfaces for integration into your production processes. All EcoMark® laser marking machines are thus perfectly suited for automated production processes and ready for Industry 4.0.

MACHINE, SOFTWARE, CONSULTING, SERVICE:

EVERYTHING FROM ONE SOURCE

We can be much more for you than just machine suppliers: We see ourselves as a partner for manufacturers in all industrial sectors where products need to be permanently and securely marked. With experience, industry know-how and innovative passion, we develop the custom-fit solution that takes you forward - and are happy to break new ground for you in the process.

Tell us what you want to laser mark! Our partnership begins with the conception and consultation and extends far beyond the installation of the marking machines in your factory. We also support you during ongoing use with fast, unbureaucratic service.

WIDE RANGE OF APPLICATIONS:

PERFECT FOR ALL MATERIALS AND SURFACES

We are also happy to think about completely new areas of application for permanent, precise laser marking. Talk to us and use our expertise for innovative laser marking machines if you want to mark specific materials or surfaces.

COMPREHENSIVE INDUSTRY KNOW-HOW:

CUSTOM-FIT SOLUTIONS FOR INDUSTRIAL USE

We are experienced suppliers of laser marking machines and partners of manufacturers with marking needs from a wide range of industries.

We offer laser marking systems for:

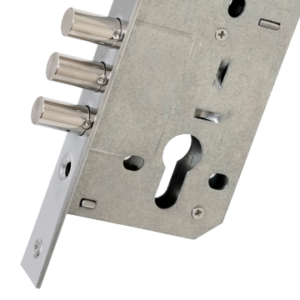

- Parts labelling in the automotive industry and its suppliers

- OEM marking laser

- Laser engravers for the metal industry and metal processing

- Marking systems for the plastics industry

- Marking laser for toolmaking

- Laser marker for pharmaceutical manufacturers and medical technology

- Industrial lasers in the field of household goods and sanitary production

- Marking systems for the packaging industry

- Laser marker for advertising material suppliers

- Marking laser for the food and beverage industry

YOU CAN COUNT ON THAT:

QUALITY IS BUILT IN AT ECOMARK

We can be much more for you than just a machine supplier: We see ourselves as a partner for manufacturers in all industrial sectors where products need to be permanently and securely marked. With experience, industry know-how and innovative passion, we develop the perfect solution to help you get ahead - and we are happy to break new ground for you.

Tell us what you want to laser-mark! Our partnership begins with the conception and consultation and extends far beyond the installation of the marking machines in your factory. We also support you during ongoing use with fast, unbureaucratic service.

THE BEST SOLUTION FOR EVERY NEED:

OUR LASER SYSTEMS FOR INDUSTRIAL MARKING

We offer all methods of laser marking, such as laser engraving, colour removal/material removal, annealing marking, colour change/foaming and carbonising.

Depending on the application, material and requirements of marking lasers, different types of lasers are used for marking by means of laser beams. CO2 lasers and fibre lasers are most commonly used in engraving machines.

- VERSATILE, COST-EFFECTIVE, EFFICIENT: CO2 LASER MARKING MACHINES

The carbon dioxide laser, or CO2 laser for short, is one of the most frequently used industrial marking lasers for laser marking, as it is very efficient and also cost-effective. CO2 lasers are particularly suitable for laser engraving of plastics and wood or for laser marking of fruit and vegetables. But also glass, rubber, cardboard, coated metals and even paper and foils can be easily laser marked with this efficient laser engraver.

This makes marking laser systems with CO2 lasers particularly versatile. Laser engraving and laser coding such as data matrix codes, barcodes, logos or product numbers can be optimally produced with the CO2 laser. Whether in the automotive industry, medical technology, the pharmaceutical industry, the metal industry or in the packaging sector: laser engraving systems with the CO2 laser are widely used for good reason. From surgical instruments in medical technology to injection moulded parts for the automotive industry and natural branding in the food industry, they guarantee permanent and high-quality laser marking for identification and traceability.

The CO2 laser offers a working hour duration of approx. 50,000 working hours. This means that laser engraving and laser marking can be carried out for more than 10 years with this marking laser. During this time, there are no consumables as with other marking solutions. The quality of the laser marking does not decrease over the years.

- POWERFUL AND EXEMPLARY ECONOMICAL: FIBRE LASER MARKING SYSTEMS

The fibre laser, also known as the "solid-state laser", together with the CO2 laser, is one of the most frequently used lasers for laser engraving in industry. The fibre laser offers the highest beam quality and energy density. It is therefore ideal for laser engraving high-density materials such as hard metal or special plastics.

In addition, the fibre laser has good cooling because the fibres have a large surface area. Laser marking of metal parts often presents challenging conditions that the robust design of the fibre laser can easily withstand. The very good contrast quality far surpasses that of the CO 2 laser for laser marking.

The fibre laser offers a service life of up to 100,000 operating hours. This means that industrial laser engraving and marking can be carried out for more than 10 years without any problems. There are no consumables as with other marking solutions. The quality of the laser engraving remains consistently high over the years.

Further advantages are the high beam quality of the generated light and the high efficiency of the conversion process, which, depending on the doping, can reach over 85 % optically. This also saves energy, among other things.

BUNDLED LIGHT ENERGY:

LASER TECHNOLOGY FOR MARKING SYSTEMS

In simplified terms, a laser beam is bundled light that achieves a very high energy density. How does it work?

LASER is the abbreviation for "Light Amplification by stimulated Emission of Radiation" and means: light amplification by stimulated emission of radiation. This light amplification is generated in the housing of the laser through the absorption and radiation of energy.

In the case of the CO2 laser, this laser-active medium is a CO2 gas mixture. Energy is supplied to the CO2 gas mixture by means of a voltage discharge, so that the light waves are generated which finally lead to the laser engraving. An opaque and a partially opaque mirror are placed at the ends of the CO2 laser, between which the light waves are reflected back and forth until they finally emerge from the partially opaque mirror as a laser beam and carry out precise laser marking.

In the case of the fibre laser, the laser-active medium that is excited to produce the laser beam is the doped core of an optical fibre. The long, thin strands of the glass fibre are about the diameter of a human hair. The laser light is guided through the glass fibre. Due to the length of the fibres, a very high amplification of the laser beam is possible. Similar to the CO2 laser, two mirrors are attached to the ends of the laser chamber to form a resonator. This creates a controlled laser for precise laser marking.