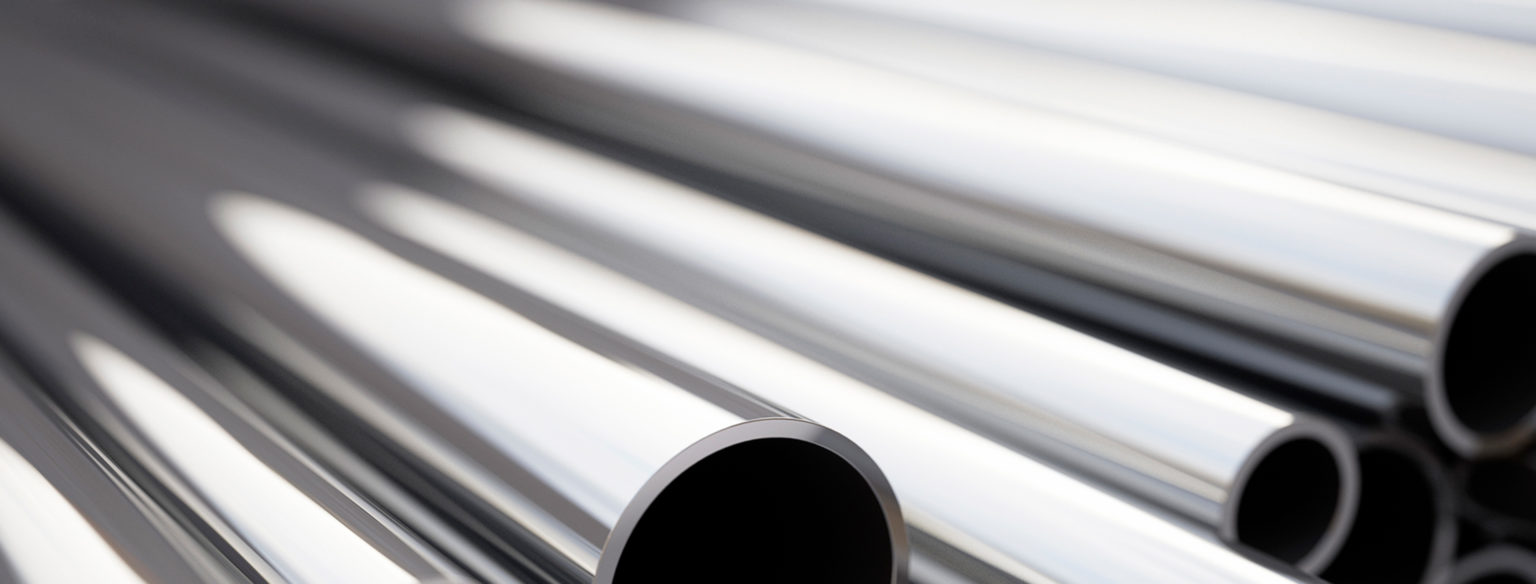

STATE OF THE ART METAL MARKING:

LASER ENGRAVER FROM ECOMARK

DIVERSITY IS THE PROGRAMME AT ECOMARK:

LASER SOLUTIONS FOR ALL TYPES OF METAL

EcoMark laser marking machines are suitable for virtually all metals and alloys: Stainless steel and mild steel, non-ferrous metals such as copper, nickel, brass and zinc, aluminium and titanium, coated and uncoated - we offer the right solution for all requirements. And if you want to laser mark changing metal parts, even more so. Because thanks to the unique EcoMark software, our machines can be quickly adjusted to new workpieces at any time, without time-consuming changeover times.

Sie sehen gerade einen Platzhalterinhalt von YouTube. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf die Schaltfläche unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr InformationenWIDE RANGE OF APPLICATIONS

IN ALL METALWORKING INDUSTRIES

- The robust laser engraving, which results in a clearly visible and tangible indentation in the metal by melting and vaporising the metal, is ideal for marking metals that have to withstand mechanical stress, for example.

- In contrast, annealing is mainly used in medical and hygiene-related areas. By heating the metal locally, a coloured oxide layer is applied, while the surface remains even, thus preventing the accumulation of germs.

- Material layer ablation, in which the coating of metals and not the primary material metal is lasered, also results in high-contrast, precise laser marking.

All three processes are durable because they are abrasion-resistant. In addition, they are insensitive to liquids such as water and oils as well as to the effects of heat.

LASER ENGRAVING OF METALS WITH ECOMARK:

ADVANTAGES THAT MAKE AN IMPRESSION

- FLEXIBLE for use on almost all surfaces and products

- FAST thanks to EcoMark software eliminates set-up and adjustment times

- COST-EFFECTIVE low-maintenance operation without consumables

- RESISTANT to mechanical stress and chemicals, heat, cold and moisture

- RELIABLE clean, permanent marking in highest precision

- LONG-lasting robust, reliable top quality

SUITABLE METALS FOR LASER MARKING

Aluminium | Coated metals | Non-ferrous metals | Bronze | Stainless steel | Hardened metals | Gold | Hard metal | HSS steel | Copper | Brass | Silver | Cast steel | Titanium