Laserkabine by EcoMark

Laserbeschriftungsanlage für Serienteile und große Bauteile

Laserbeschriftungsanlagen für die Industrie 4.0 eignen sich für eine flexible und automatisierte Laserkennzeichnung. Durch die automatische Vergabe von Seriennummern können kleine und mittlere Serien, sowie große Bauteile bis zu 1.400 mm Länge beschriftet werden.

HOCHWERTIGES BRANDING

IN DER INDUSTRIE

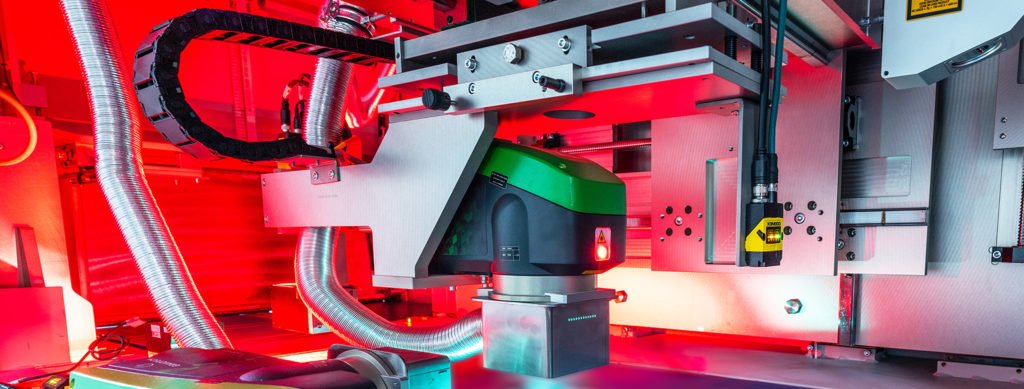

Laserbeschriftungsanlage für kleine und mittlere Serien und Bauteile bis 1.400 mm Länge

Laserbeschriftungen oder Lasermarkierungen finden Anwendung in unterschiedlichen Branchen, wie z. B. in der Automobilindustrie, in der Luft- und Raumfahrtindustrie, in der Medizintechnik oder in der Pharma- und Lebensmittelindustrie. Eine Vielzahl von Daten, darunter Barcodes, Texte und/oder Nummern können direkt auf die Werkstücke gelasert werden. So entfallen Verpackungs- und Kennzeichnungsmaterialien wie Aufkleber und Papier und Plastik. Weitere Vorteile wie Beständigkeit gegen mechanische Beanspruchung und Chemikalien oder auch die sehr geringen laufenden Kosten und die Wartungsfreundlichkeit, runden das Angebot der Laserkennzeichnung ab. Mit einer Laserbeschriftungsanlage haben Sie ein zuverlässiges Industrie 4.0 -fähiges Kennzeichnungssystem!

BESONDERHEITEN UNSERER LASERBESCHRIFTUNGSANLAGEN

LASERBESCHRIFTUNGSANLAGEN READY FÜR DIE INDUSTRIE 4.0

Die Laserkennzeichnung in unseren Beschriftungsanlagen eignet sich für kleine und mittlere Serien, sowie für Bauteile bis 1.400 x 750 x 500 mm.

Mit der EcoMark Laserkennzeichnungsanlage können beliebig viele Laserungen im 3 dimensionalen Raum durchgeführt werden. Jede Laserung kann sich dabei auch unterscheiden.

Der verfahrbare Laser kann X, Y und Z-Koordinaten mit verschiedenen Laserinhalten abfahren.

- VERFAHRBARER LASER AUF 3 ACHSEN

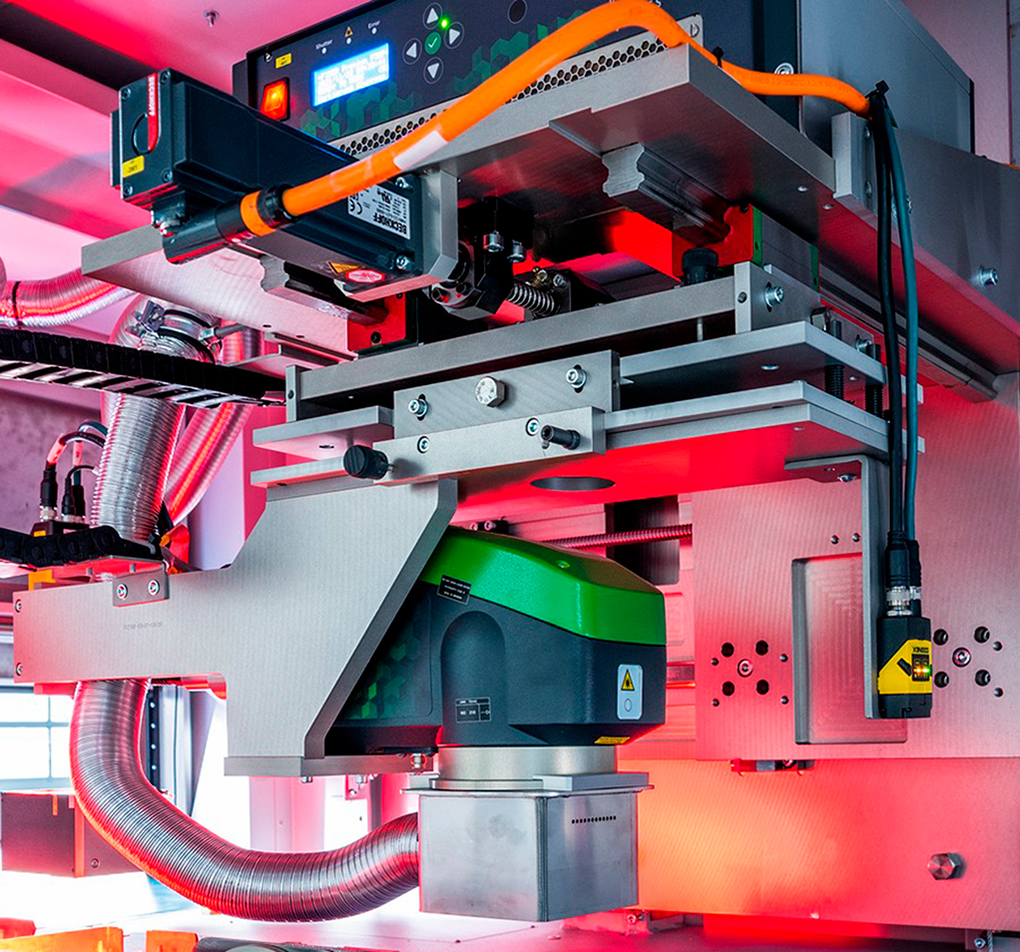

- MODULAR AUFGEBAUTE ANLAGE

Die Laserbeschriftungsanlage ist modular aufgebaut und verfügt über viele anpassbare Optionen:

- Große manuelle Tür oder automatische Hubtür

- Große seitliche Türen

- Windows Industrie PC

- Diverse Schnittstellen über die EcoMark-Software

- Integrierte Steuerung

- Adapter für alle führenden Laserhersteller

Sie sehen gerade einen Platzhalterinhalt von YouTube. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf die Schaltfläche unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr Informationen- AUTOMATISCHE GENERIERUNG VON SERIENNUMMERN

Die Laserbeschriftungsanlage ist einfach programmierbar für die

automatische Kennzeichnung von Serien.

Zum Markieren von Werkstücken besteht außerdem die Möglichkeit, vollautomatisch IDs oder Seriennummern zu generieren.

Die moderne und einfach bedienbare Software der Anlage ist fertig für Industrie 4.0 und es werden keine Programmierkenntnisse benötigt. Sie ist für die Verwaltung von Produkten, Kunden, Aufträgen und Benutzerrechten bestens geeignet.

Es besteht die Möglichkeit zur Übernahme von Daten aus ERP- oder Produktionssystemen. Optional kann auf allen EcoMark Laserkennzeichnungsmaschinen für Metall oder Kunststoff auch eine OPC UA Schnittstelle eingerichtet werden.

Sollten Fragen aufkommen, können wir über die Fernwartung in der Regel schnell helfen.

- EINFACHE BEDIENUNGSSOFTWARE

LASERBESCHRIFTUNG IN LASERBESCHRIFTUNGSANLAGEN

ANHALTENDE UND SICHERE KENNZEICHNUNG

Laser schreiben extrem schnell, dauerhaft und zuverlässig. Der Vorteil bei Lasern ist, dass sie keine Verbrauchsmaterialien wie Tinte, Farbbänder oder Etiketten benötigen. Der Laser beschriftet berührungslos, weshalb auch leicht gewellte und empfindliche Oberflächen einfach beschriftet werden können.

Die zu erwartenden Lebensdauer von Lasern liegt je nach Laser zwischen 50.000 und 100.000 Betriebsstunden. Als Betriebskosten fallen weder Verbrauchsmaterial noch Wartungskosten an!

Für unterschiedliche Aufgabenstellungen und Materialien werden verschiedene Laserarten und Leistungsstärken in unsere Lasermaschinen verbaut:

CO2-LASER

Der Kohlenstoffdioxidlaser gehört zu den am häufigsten industriell eingesetzten Lasern zur Laserbeschriftung. Eine CO2-Laserbeschriftungsmaschine ist sehr effizient und kostengünstig, dieser Typ eignet sich für ein breites Anwendungsspektrum in der Industrie. Als erfahrene CO2-Lasermarkiermaschinen-Lieferanten beraten wir Sie gerne über die für Sie passende Lösung.

FASERLASER

Der Faserlaser oder auch Festkörper- Laser ist ebenfalls weit verbreitet für Anwendungen in der Lasergravur. Der Faserlaser bietet höchste Strahlqualität sowie Energiedichte. Er ist somit ideal, um Materialien mit hoher Dichte mit einer Lasergravur zu versehen. Ob eine Faserlasergravurmaschine für Sie das Richtige ist, besprechen wir gerne mit Ihnen.