METALL-KENNZEICHNUNG STATE OF THE ART:

LASERGRAVIERER VON ECOMARK

VIELFALT IST BEI ECOMARK PROGRAMM:

LASERLÖSUNGEN FÜR ALLE METALLARTEN

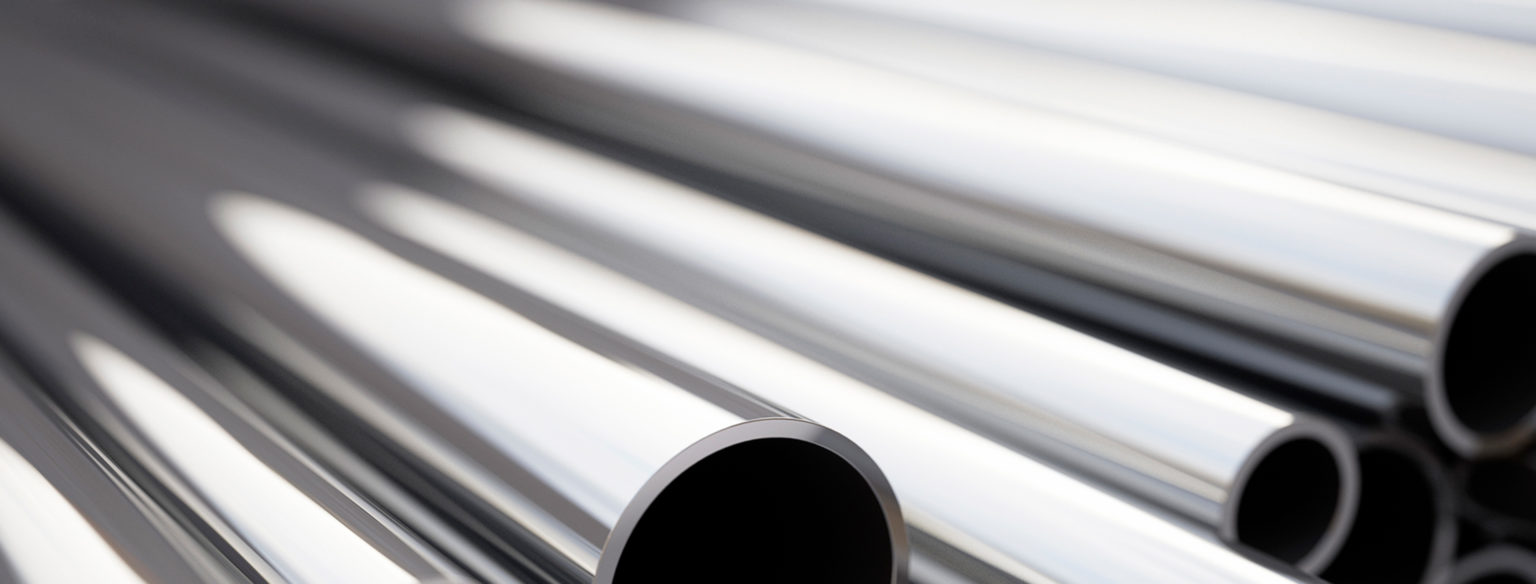

Laserkennzeichnungsmaschinen von EcoMark eignen sich für praktisch alle Metalle und Legierungen: Edelstahl und Baustahl, Buntmetalle wie Kupfer, Nickel, Messing und Zink, Aluminium und Titan, beschichtet und unbeschichtet – wir bieten für alle Anforderungen die passende Lösung. Und wenn Sie wechselnde Metallteile laserbeschriften wollen, erst recht. Denn dank der einzigartigen EcoMark Software lassen sich unsere Maschinen jederzeit schnell auf neue Werkstücke einstellen, ohne aufwändige Umrüstzeiten.

BREITES ANWENDUNGSSPEKTRUM

IN ALLEN METALLVERARBEITENDEN BRANCHEN

- Die robuste Lasergravur, die durch Schmelzen und Verdampfen des Metalls zu einer deutlich erkennbaren und fühlbaren Vertiefung im Metall führt, eignet sich zum Beispiel ideal zur Kennzeichnung von Metallen, die mechanischen Beanspruchungen standhalten müssen.

- Im Gegensatz dazu findet die Anlassbeschriftung vor allem in medizinischen und hygienerelevanten Bereichen Anwendung. Durch die lokale Erhitzung des Metalls wird eine farbliche Oxidschicht angebracht, die Oberfläche bleibt dabei eben, wodurch eine Anlagerung von Keimen verhindert wird.

- Auch der Materialschichtabtrag, bei dem die Beschichtung von Metallen und nicht der primäre Werkstoff Metall belasert wird, führt zu einer kontrastreichen, präzisen Laserbeschriftung.

Alle drei Verfahren sind dauerhaft, da sie abriebfest sind. Zusätzlich sind sie unempfindlich gegenüber Flüssigkeiten wie Wasser und Ölen sowie Wärmeeinflüssen.

LASER GRAVIEREN VON METALLEN MIT ECOMARK:

VORTEILE, DIE EINDRUCK MACHEN

- FLEXIBEL einsetzbar für nahezu alle Oberflächen und Produkte

- SCHNELL dank EcoMark Software entfallen Rüst- und Einrichtzeiten

- KOSTENGÜNSTIG wartungsarmer Betrieb ohne Verbrauchsmaterialien

- BESTÄNDIG gegen mechanische Beanspruchung und Chemikalien, Hitze, Kälte und Feuchtigkeit

- ZUVERLÄSSIG saubere, dauerhafte Kennzeichnung in höchster Präzision

- LANGLEBIG robuste, zuverlässige Top-Qualität

GEEIGNETE METALLE ZUR LASERKENNZEICHNUNG

Aluminium | Beschichtete Metalle | Buntmetalle | Bronze | Edelstahl | Gehärtete Metalle | Gold | Hartmetall | HSS Stahl | Kupfer | Messing | Silber | Stahlguss | Titan